Join us at The Paris Airshow 2019

Eliminating waste and adding value to production lines is a deep-rooted focus of Middlesex Aerospace. Through joint lean events and project coordination with KLX, jointly resourced service teams have designed a best fit kitting solution to enable clear visibility up and down stream of the supply chain. Full traceability, certifications and customized labeling requirements are supported through the kitting infrastructure.

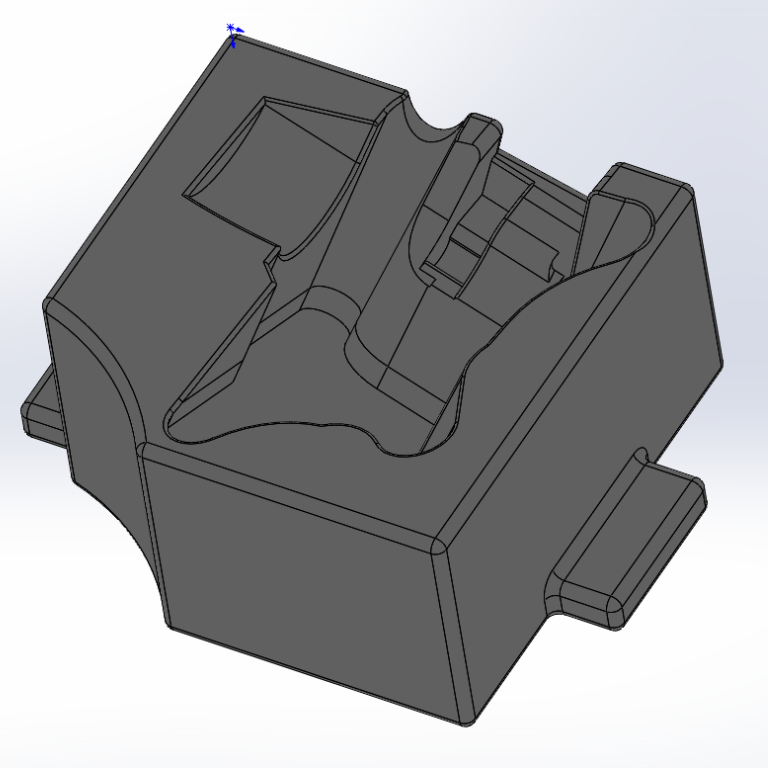

Cross functional teams took assembly detail directly from the Bills of Materials and Assembly Work Details. Kitting design experts then delineated all the data, part numbers, and tribal knowledge into clear visual instructions printed directly on the custom-designed kit box.

A comprehensive suite of management reports were also defined to ensure clear visibility of the supply chain capacity and identify any early warning signals. KPIs and business intelligence have been tailored to meet the needs of Middlesex Aerospace teams and provide a basis for all contract management meetings.

The results are clear and offer a multitude

of benefits program wide.

46 separate part numbers, including

16 drawn items and all associated requirements now reduced to 1 part number

Booking in/out reduced from 4 hours per batch to 30 minutes

Operation sequence part lay out, mistake-proof coordination, exact unit count

preparation, full customization to part

type, size, quantity and integration of

specific assembly instructions (i.e. peer

check, stop points, etc.)

Reduction of 60% in generation of C Of C’s

Collect and layout reduced from 3.5 hours per batch to 30 minutes – time saved equal to 1 day per week

8 hours saved per month, reduction from 102 invoices per month to 1

Reduction from 7.5 hours per month to 1 hour

Saved valuable floor space in stores area

The expectation from the joint initaive is that this activity will result in a 50% reduction in kitting time and eliminate shortages at the site level.

This will be accomplished via precounting and presenting parts within the same operation sequence as the aforementioned kits.

Middlesex Aerospace have worked collaboratively with the cross functional teams to deliver a world class service model enabling greater visibility of supply chain capacity.

The outcome of this collaboration is a shared vision of success for the future, the flexibility to respond to a changing market and enhance our ability to surpass the service expectations now and drive continuous improvement into the future.