At Middlesex Aerospace we are serious about improvement and see a problem as both a challenge and an opportunity to grow. We have introduced one of the key communication tools used in lean environments and the results are clear to see with a positive impact in both communication and response time.

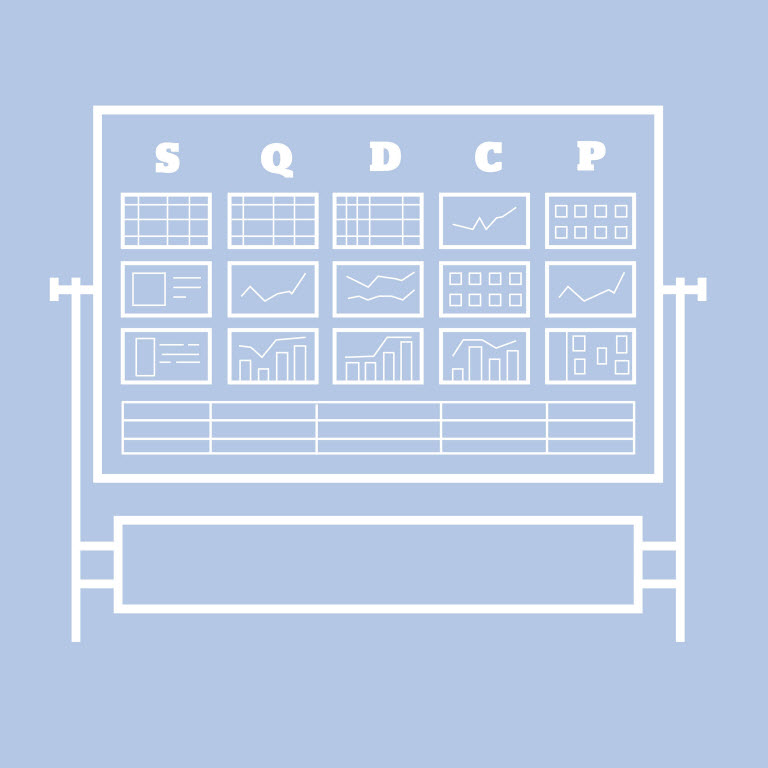

The SQDCP (Safety, Quality, Delivery, Cost & Performance) visual management board.

Middlesex Aerospace’s introduction of SQDCP (Safety, Quality, Delivery, Cost & Performance) boards throughout our key work streams within the factory has demonstrated a positive impact in communication and response time.

The use of the boards enable us to efficiently communicate potential improvement opportunities every morning, have a positive input and involvement from all staff and convey expectations for the day clearly and accurately. The boards are also a focal point for any issues arising that need to be dealt with quickly and effectively throughout the 4 tier structure. This enables us to quickly adapt our operational activities to meet both internal and external drivers.

The SQDCP board is a methodology introduced to us through the SiG (Sharing in Growth) program that quickly conveys how the process is performing against these 5 categories. These KPI’s cover both internal and external measurements that enable us to see the bigger picture in an easy to read format for all staff. The daily meetings last for no more than a short 15 minute interval, before business cell leaders take any feedback to the following tier, this is where information can be passed through the tiers quickly and effectively and if required have a response from senior management.

The implementation of the SQDCP boards has

- Facilitated involvement from all levels within the business

- Provided visibility which in turn increases drive to improve KPI’s

- Improved internal communication

- Brought flexibility to manage customers’ requirements

- Developed a culture of continuous improvement now growing throughout the business.