As a leading aerospace company we constantly strive to deliver the best solutions to our clients. Our on-going focus remains on reducing lead times, engineering costs and for this project quicker response time to spares and OE (Original Equipment) manufacture.

Investment

Recently we made the decision to invest in Plastic Additive Manufacturing Technology to support both internal and external influences.

Research and testing

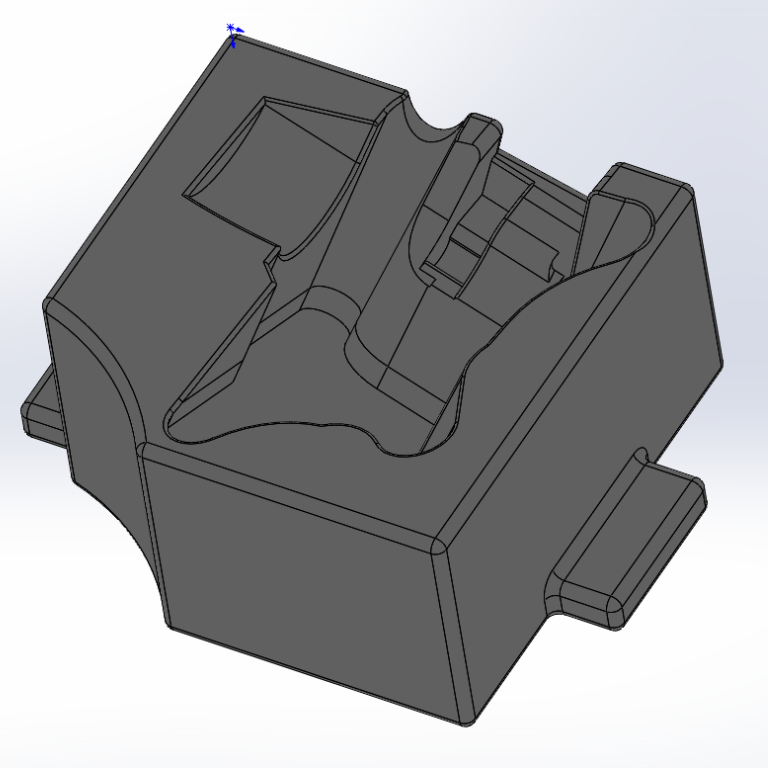

With the technology installed our teams successfully designed and manufactured specialist fixtures for a number of applications including part marking, assembly and testing. For particular applications involving heat and oil, we researched and conducted a number of tests using available material within the marketplace to ensure accuracy and consistency, this ensured that we could capture other variables such as the lifespan of material before they breakdown.

Embedding into our processes

Being able to print required fixtures straight from an imported Solidworks model into specialist software enables us to save time and therefore the associated costs for our customers when drawing the parts for tool manufacturers.

Results

The results are clear to see

- Lead time in procuring fixtures reduced by up to 6-8 weeks.

- Cost reduced by up to 80% in particular applications.

- Engineering content (Dimensioning Model) reduced by 50%