Managing Director Laurie Foulds features in the June issue of Aerospace Manufacturing for their Final Approach article.

According to Middlesex Aerospace’s managing director, Laurie Foulds, a continuing boom cycle ensures there is plenty of business to be done out there in the world of aerospace manufacturing.

I’ve been working in the aerospace sector for over thirty years and it’s worth remembering that for most of that time, the industry was in a cycle of boom and bust – it is only in the past decade or so that the bust part of the cycle seems to have vanished. Certainly, the current trade difficulties between China and the US might suggest that the high point of the cycle has been reached.

Even so, there is plenty of business to be done out there in the world. Last year, we placed the largest order ever in our 75-year history for new machine tools. The first was delivered in December and is already full; the second one is ready to be shipped and the final deliveries will all be complete by the end of the year. After that it’s a question of assessing customer needs and judging capacity as a result.

When I first started in aerospace, our competition would usually be our customers own machine shops or a handful of companies, all of which I would probably have been aware of. Today, of course, that is no longer the case and many of our new competitors are now from Asia. That is no surprise and whilst globalisation has caused many problems in the West, it has undeniably lifted millions out of poverty in the developing world, and these people are naturally hungry for the comforts we in the West have grown used to over decades. This is tough competition, but I for one am not afraid of it. The more we automate and improve efficiency, the less it matters what labour cost is, and so we can have a highly paid and skilled workforce and still be internationally competitive.

Certainly, improving productivity of machine tools through automation and more creative use of data is one of our key strategies over the next few years. We have taken on apprentices every year since 1950 and have trained well over a thousand since then, and over half our management board are ex-apprentices. G etting our highly-skilled people to best use all this exciting new technology is the way in which we will use these investments to continue to produce best quality, cost and delivery for customers old and new.

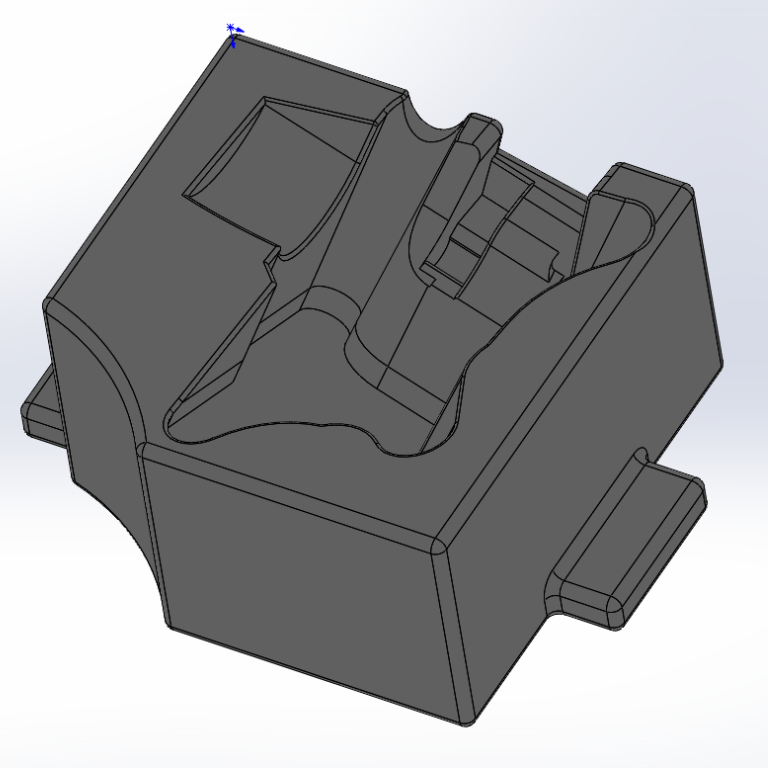

Advanced machining technology, whilst important, isn’t the whole story. Our customers are increasingly looking for partners that can provide a complete turnkey service from product inception through to prototype and finally delivery of an up and running OE programme. We have been working with our customers for many years to hone aspects of the design of products – as we all know, once the drawing is sealed, most of the costs are too – but increasingly, we are supporting additional areas too. In the distant past, all of our customers had their own machine and processing shops, but now many of them don’t, and as a consequence, the knowledge they have in these areas isn’t as great as it once was.

Accordingly, we have deliberately set out to enhance our supply chain management with a view to being able to recommend and ultimately approve sources for special processes, materials and so on. We have carefully selected partners for processing, raw material supply and ‘bought out finished’ support, and we all work together to offer a comprehensive package for complete units. Security of supply is a prime concern for our customers. We can offer dual sourcing of machining, processing, material supply and assembly, so if one facility is affected then the other can support OE build in the meantime until a complete suite of supply is restored.

When my father started in business 75 years ago, he could have had no idea where we would be today. However, there are several aspects of the Middlesex story that are as true today as they were then, and they are our core values of delivering excellence, doing business with integrity, and working to bring out the best in people. We will continue to do that and I look with confidence to an exciting future for us all.

Aerospace Manufacturing June 2019