For any young student looking at their choices after school the same question will always come up; What’s an apprenticeship like? Is it really a viable option to university? And does it really contain a mix of academic study and practical experience?

The best way to answer that is to ask some of our apprentices here at Middlesex Aerospace. So, we came up with a few questions to put to them. Here’s how Tomasz and Alan have found the experience of learning in a work environment during the first steps towards an exciting career as an engineer in the aerospace sector.

What made you decide to join an engineering apprenticeship?

Tomasz: I decided to take on the challenge of an apprenticeship to help me improve my problem-solving skills and practical skills. Working in engineering allowed me to learn real life skills and opened new opportunities for me.

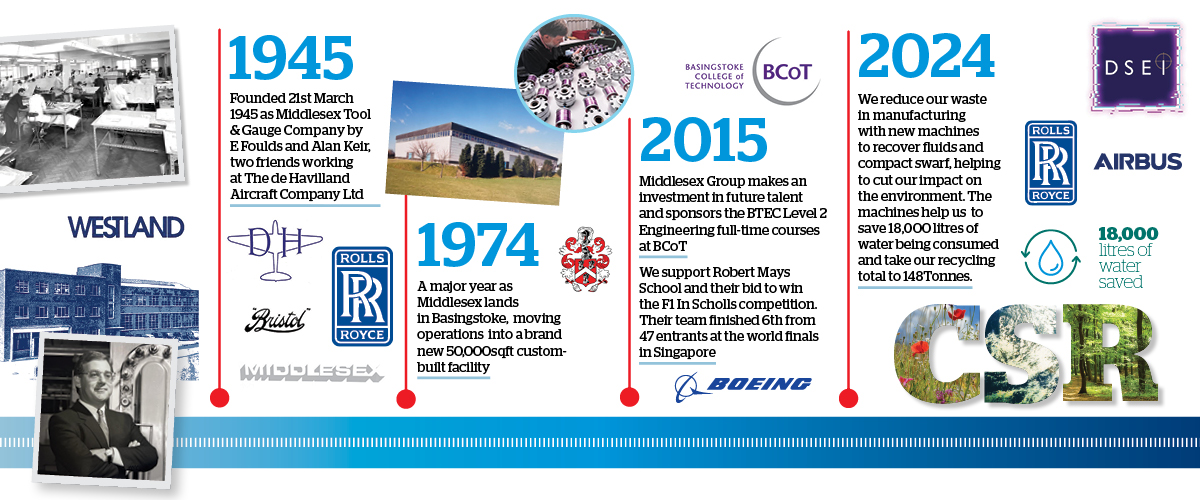

Alan: From a young age, I was inspired by my grandfather, an engineer for AWE and Lancing Bagnall, and always loved exploring how things worked. In secondary school my DT teacher, Mr. Wills, encouraged me to attend an open evening at BCoT. I initially went with motorsport in mind but became captivated by engineering. I discovered Middlesex Aerospace and was fascinated by the helicopter parts they showcased. That experience solidified my interest and eventually secured an apprenticeship.

Has the reality of life as an apprentice matched your expectations?

Tomasz: Working in an engineering environment has been a fulfilling experienced that taught me things I never knew existed.I see and learn new things everyday at my apprenticeship which so far has made my experience positive and certainly lived up to my expectations.

Alan: I expected more hands-on work, which has been true, but it’s also been great to see the full scope of the business. Day-to-day life hasn’t held many surprises but has kept me engaged with a mix of tasks.

What made you choose to be an apprentice engineer rather than study full-time?

Tomasz: To choose the ability to study and work at the same time was a game changer for me. When I complete my Apprenticeship I will have learned real world experience and managed to get my diplomas in engineering courses. This means I am more valuable to employers and also have the choice to further educate myself in university.

Alan: I wanted the balance of earning while learning and gaining hands-on experience. Working with experienced engineers has given me insights beyond a classroom setting. Having both college and on-the-job learning means I can apply theories practically, and even compare approaches between work and college, using each as a grounding point.

How do you find the mix of college study and on-the-job learning?

Tomasz: Going to college and work on a weekly 20/80 split is a healthy mix between learning practical and theoretical skills. It allows for positive ideas to be shared between fellow apprentices from different companies. This broadens knowledge on different industries and companies around your local area.

Alan: The overlap between college theory and practical work is limited, except in areas like project management. My strategy has been straightforward: tackle tasks as soon as possible and aim to do them well.

Has learning practical skills given you a better insight into how you want to pursue your career?

Tomasz: During my apprenticeship I get to cover many subjects and work in different departments in my workplace. This gives me a clear view into engineering companies and what opportunities these companies have to offer me. So I have a broad insight into career paths they want to dive into upon completion of their apprenticeship.

Alan: Definitely. Through my HND, I’ve become interested in CAD design and simulation, and working with real-world equipment has also shaped my specialization goals.

What would you say to students looking at their career options in engineering?

Tomsz: Apprenticeships prepare you for difficulties and responsibilities you will encounter when working full time in the engineering industry. You will learn how to communicate with others, work with machines, tools and computer software. This is what’s an apprenticeship like. They are a fantastic choice for passionate young people and students. You learn a broad range of interesting skills that will set you up positively for the future.

Alan: I’d recommend apprenticeships, not just for hands-on roles but for opportunities across engineering firms in areas like finance, purchasing, or IT. I became a CMM programmer—a field I hadn’t considered before joining Middlesex Aerospace. My advice: focus on continuous improvement, and remember that sometimes bringing a fresh perspective is as valuable as following established practices.

If you are looking at your post-school options and want to follow a career in engineering, make sure you get yourself to a BCoT open day to discover more about their excellent courses. You can also contact us to find out how you can become an apprentice with Middlesex Aerospace.