With a name synonymous with advanced engineering of the highest quality, and one of the UK’s leading suppliers to the aerospace sectors we are 80 years old this month – and celebrating our history with a promise to keep looking ahead to the future.

In March 1945, with the Second World War nearing the end, engineering draughtsman Emerson Foulds founded the Middlesex Tool & Gauge Company. Over the years the company has grown to include many iconic names as customers, including Rolls-Royce, IBM, Chubb, BAE and Airbus. Today, the business is known as Middlesex Aerospace and employs over 100 staff at their advanced facilities in Basingstoke. From here we deliver precision engineering services for major aerospace firms around the world.

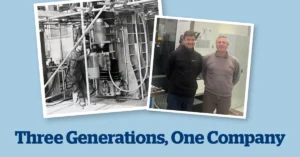

“Throughout our history we have continuously invested in people and technology,” said Laurence Foulds, CEO and son of founder Emerson. “It is the only viable way to stay at the forefront of quality and service to help our partners reach new heights in aerospace. Our vision is to continue to combine the latest technology with finding and nurturing talent engineers, both now and in the future.”

A history in building for the future

For over 75 years Middlesex Aerospace has operated an Apprenticeship Scheme, helping local school leavers turn into highly skilled and experienced engineers. “Our staff include many people who joined us straight from school, and we are proud of our track record in helping young people enjoy a long and fruitful career in engineering,” said Laurence.

Along with creating talented engineers, Middlesex Aerospace has continuously evolved to introduce new services to customers and expand their facilities when possible. “We are looking to grow capacity in the near future”, said Laurence, “and roll out additional services which will benefit our customers.”

“Being here after Eighty years is a major achievement and testament of the drive and talent of our staff. Now, with our people and desire to reach new heights in precision engineering, Middlesex Aerospace can look ahead to an exciting future.”