NDT

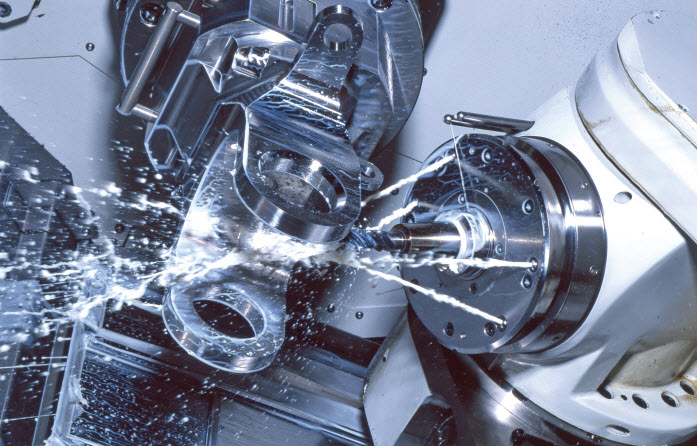

Non-destructive testing (NDT) is a highly important stage in ensuring you receive components that meet or exceed set standards. Through rigorous, careful inspection, NDT provides valuable insight into the quality, integrity and safety of a product and the processes used to create it.

But while NDT is an essential stage for precision engineering, this can also create complexity in the value chain. Where a third party is used for this, the logistics involved in sending and receiving products for inspection can result in delays before completing a project. The logistics involved place a risk of products being damaged in transit. And there is the security element too for items of a sensitive nature.

To help reduce these issues, Middlesex Aerospace provides NDT testing services within our manufacturing process to provide the assurance that your components are produced to the highest quality standards. Delivered by staff working to exacting standards, testing can be undertaken to evaluate a range of criteria including individual parts or built-up components and the materials and processes they comprise.

The benefits of NDT from Middlesex Aerospace

NDT from Middlesex Aerospace results in a tangible improvement in:

- Delivering finished components that meet or exceed standards. Giving you confidence your product is safe to use and will perform as intended

- Reducing faulty products by discovering flaws or issues that can affect the serviceability of the components before they are put into service

- Providing reliable consistency of supply, through continual monitoring of produced components for accuracy and conformity to the most exacting specification

You can utilise Middlesex Aerospace NDT services for the following areas:

- Penetrant Flaw Detect: analysing cast, treated and machined surfaces for any flaws that could impair performance or reliability

- Magnetic Particle Inspection: uninvasive investigation for surface and near surface flaws and cracks in components made from ferromagnetic materials

- Etch Inspection: A visual inspection method which highlights any inconsistent machining or grinding to items in manufacture

- Hardness Testing: Physical testing of surfaces to determine their strength to determine their wear resistance and conformance to your specification.

Quality NDT Testing Approved by NADCAP

NDT testing for the most demanding of applications is more than desirable – it’s essential. Middlesex Aerospace provides a range of NDT services approved by the National Aerospace and Defence Contractors Accreditation Programme (NADCAP). With NADCAP approved testing from Middlesex Aerospace your value chain delivers a high quality finished product for improved reliability and performance.

The Flexible NDT Service You Can Trust

Middlesex Aerospace NDT services are available to match your needs. They can be included as part of manufacture of parts within our facility, making supply efficient and seamless. Alternatively, you can utilise our services within your value chain to help partners deliver to required standards.

Where you need NDT services provided quickly, Middlesex Aerospace can also deliver a priority service to support your project. Delivering expert inspection and analysis that does not compromise on quality.